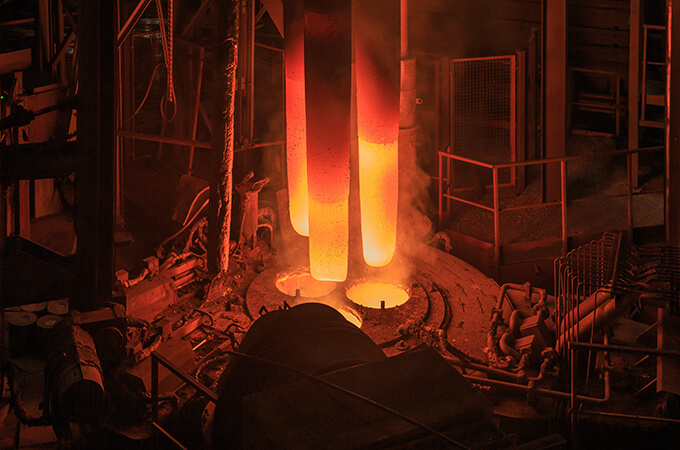

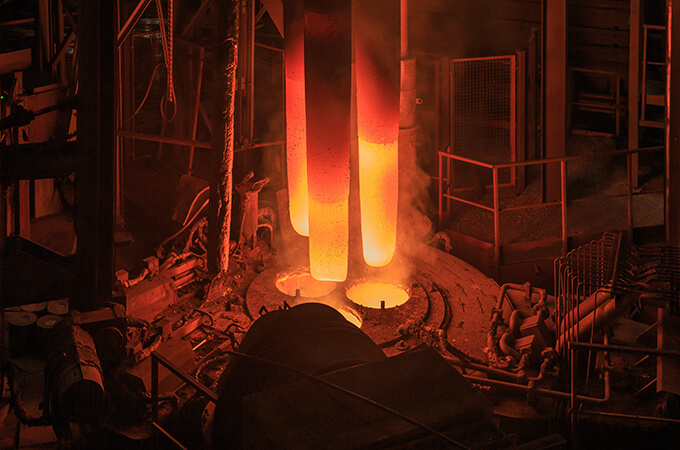

Lime for the iron and steel industry

Lime in the steel industry is essential for steel quality

Lime is a key raw material in modern steel production, playing a crucial role in multiple stages of the manufacturing process. Thanks to its unique chemical properties, it is vital for the removal of impurities such as sulphur and phosphorus, contributing to the production of high-quality steel.

With over 300 years of history, Fassa Bortolo has developed a deep understanding of the steel industry’s needs, translating this knowledge into a comprehensive range of specialised products. Our continuous commitment to research and development has enabled us to evolve alongside the sector, creating innovative solutions such as the low-carbon ELC line and Flow Lime products.

Applications of quicklime in the iron and steel industry

Lime for pig iron production

In the sintering process of iron ore, hydrated lime and calcium carbonate are essential for obtaining the raw material for pig iron. Our manufacturing process ensures lime with a constant and controlled composition, which is essential for stable sintering performance.

Lime for desulphurisation and dephosphorisation

Our highly reactive quicklime optimises the removal of sulphur and phosphorus from steel. Its high purity and reactivity enable superior results with lower material consumption, reducing operating costs in the refining process.

Lime as functional additive for the slag

Our dolomitic mixtures strategically combine high-calcium and dolomitic lime, optimising storage while ensuring the required reactivity from the calcium component. The controlled MgO content makes slag less aggressive towards refractory linings, significantly extending their service life and reducing steel plant maintenance costs.

Lime for reducing furnace lining wear

Our dolomitic mixtures strategically combine high-calcium and dolomitic lime, optimising storage while ensuring the required reactivity from the calcium component. The controlled MgO content makes slag less aggressive towards refractory linings, significantly extending their service life and reducing steel plant maintenance costs.

Our high-MgO dolomitic lime has been developed to extend refractory life. Its high magnesium content helps protect furnace linings, greatly reducing maintenance costs.

The advantages of lime for the iron and steel industry from the Fassa Bortolo – Lime System

Choosing the Lime System for the iron and steel industry means relying on a partner with in-depth sector expertise. Our lime is produced using state-of-the-art technologies and PFRK kilns (Parallel Flow Regenerative Kilns), ensuring maximum energy efficiency.

We offer not only high-quality products but also a complete service that includes specialised technical consultancy, tailored logistics solutions and ongoing support to optimise production processes.

With four strategically located production sites, we guarantee prompt supply and a widespread service network, confirming our role as a trusted partner for the steel industry.

- State-of-the-art technology for maximum energy-efficient production

- Specialised technical support and customised logistics solutions

- Network of four strategic production plants for timely supply

- Reliable partner with extensive steel industry experience

- Products with EPD certification

Discover the full range of lime products for the iron and steel industry

Calcitic Quicklime

ELC

Flow Lime

Dolomitic Quicklime

Flow Lime 40%

Dolomitic Mixtures

At the excellence of lime, we add tailor-made services for your sector

Customised products

Thanks to our full control over the production chain and our own quarries, we can offer tailor-made products that perfectly meet your specific technical requirements. Our multiannual of experience supplying lime to various industrial sectors allow us to develop bespoke solutions, precisely calibrating both the physical and chemical properties of the final product. With Fassa Bortolo, you have a partner who knows how to turn your needs into concrete solutions.

Solutions for product storage and dosing

We provide you with state-of-the-art storage and dosing systems for air lime, designed to ensure continuity in your production process. Our silos, available in both pressured and gravity-fed versions, adapt perfectly to your operational needs. Whether you need to manage production peaks, plan maintenance, or test new products, our technical team will support you in identifying and installing the most suitable solution for your industrial process.

Development of customised equipment

We design and build customised plants to meet your specific lime usage requirements. Our approach starts with an in-depth analysis of your needs: we conduct site inspections, assess feasibility, and develop solutions that combine your technical requirements with your budget. A collaborative process to transform your needs into effective and practical projects.

Drafting of specific technical reports

Our experts are ready to visit your facility to analyse your specific needs and propose the most efficient solution. We evaluate every aspect together, from storage and dosing equipment to selecting the product best suited for your production process. Our consultancy guides you towards the optimal combination of products and technologies to maximise your plant’s efficiency.

Analysis of materials

At our Fassa I-Lab research centre, we have cutting-edge equipment to carry out thorough and comprehensive material analyses. From mineralogical testing to compositional analyses, from porosity evaluation to grain size studies, our team of experts uses state-of-the-art technologies to provide you with precise and reliable results. A complete service that allows you to understand and optimise your product characteristics.

Transport

We guarantee punctual and reliable deliveries thanks to our optimised transport service. Our commitment is to ensure your products arrive exactly when and where you need them, strictly respecting agreed methods and schedules.

Assistance

We provide you with comprehensive technical support, backed by decades of field experience. Our expert team will not only offer you standard support but is ready to intervene promptly to resolve any specific issues with your plant, ensuring operational continuity and maximum efficiency.

Latest updates from the Lime System – Fassa Bortolo

Explore products designed for your sector

Our technicians are available to guide you in selecting the best product for your processes.