ELC

The quicklime line with low carbon content. With a high CaO concentration, outstanding reactivity and minimal impurities, it is the ideal choice for the production of low-carbon and stainless steels.

Home | Products | Quicklime Line | ELC

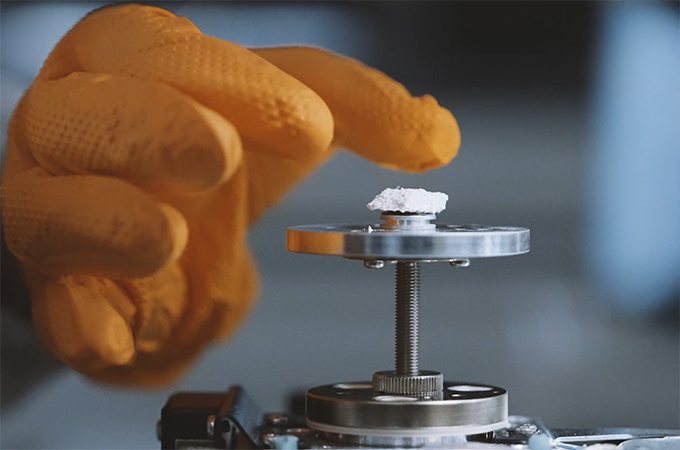

The ELC line has been specifically developed for the production of low-carbon and stainless steels. Thanks to our innovative firing method and the use of biomass as fuel, we produce lime with unique characteristics: extremely low CO₂ content, high reactivity and exceptional purity.

The high available CaO content, combined with elevated reactivity, ensures superior performance throughout the steelmaking process. The consistent quality of our raw materials, carefully selected and controlled, guarantees a final product that meets the most stringent requirements of today’s steel industry, where every element must contribute to delivering an excellent end result.

Our commitment to environmental sustainability is officially certified through our Environmental Product Declaration (EPD). This document, based on a rigorous Life Cycle Assessment (LCA), offers a transparent and scientific evaluation of our products’ environmental footprint.

| Supply formats | |||

|---|---|---|---|

| Grain size | Silo truck | Dump truck | Big bags |

| 3-9 mm | |||

| 8-20 mm | |||

I nostri tecnici sono a tua disposizione per offrirti una quotazione su misura.